High Voltage Electrical Safety – Designing in Layers of Protection

This article offers an in-depth look at topics related to Functional Safety and Electric Mobility.

For expert-level training—including certification-based programs—on these topics and more, explore our Automotive trainings. To learn how we support product development, compliance, and organizational safety goals with consulting support, visit our Functional Safety & Cybersecurity and Electric Vehicle Development pages—or contact us directly.

The effects of voltage on the human body depend on many parameters including physiological (anatomy of the body), skin wetness, contact area, duration of exposure, and voltage level and type (alternating current (AC) vs. direct current (DC)). Due to this variance, it is difficult to establish an exact threshold between safe and unsafe contact voltages for all humans in all conditions. However, it is widely accepted in the automotive industry to define high voltage (HV) as voltage levels greater than 30 VAC rms and 60 VDC [SAE J1766, FMVSS 305, ECE R100]. Therefore, voltages equal to or greater to these HV thresholds are considered unsafe and require protective measures to prevent harm from electrical shock such as cardiac arrest, breathing arrest, burns, cellular damage and ventricular fibrillation.

Applying layers of protection is commonly used for protective measures regarding electrical safety of HV systems. This is a familiar approach used for safety in many industries, and even similarly in cybersecurity with layers of defense. In functional safety standards, such as the IEC 61508 and IEC 61511, the semi-quantitative Layers of Protection Analysis (LOPA) is conducted to evaluate the residual risk after applying various protection measures. Examples of protection layers in the LOPA include general design, control systems, alarms and restricted access. Each protection layer should be independent for another protection layer and should be capable on its own of preventing the hazardous event of concern.

For HV electrical safety we apply four layers of protection:

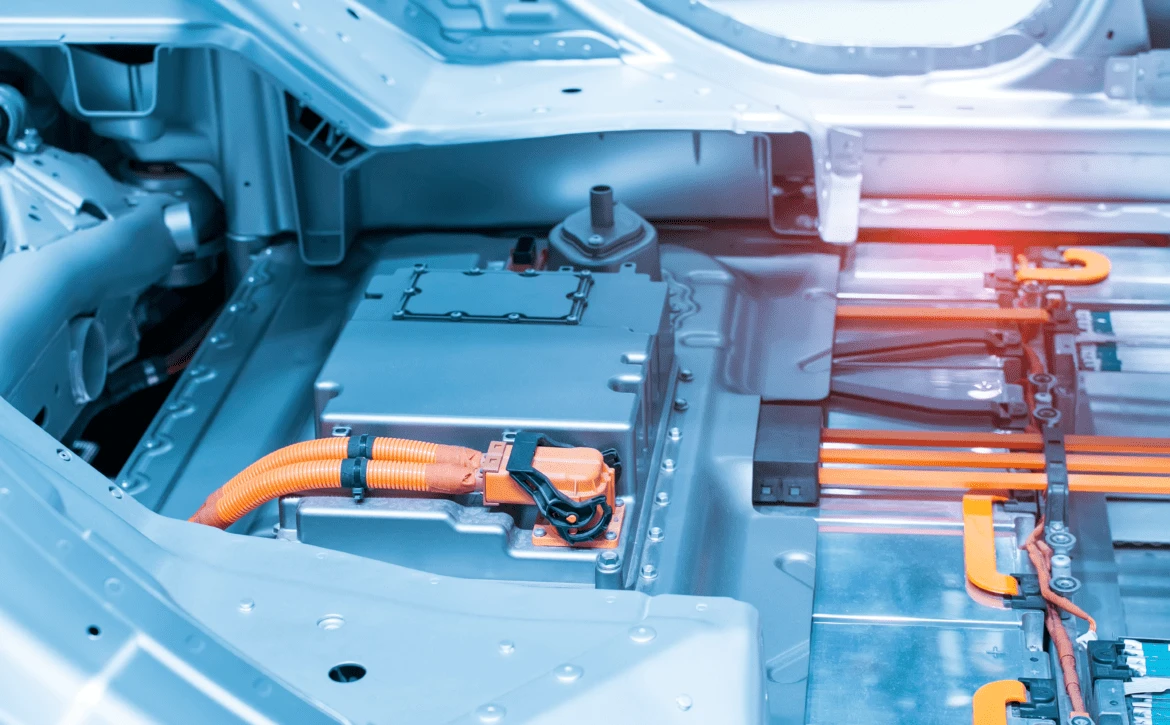

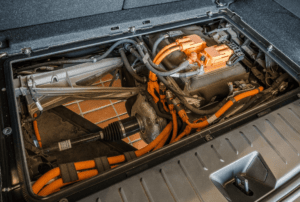

- Physical Protection: This layer ensures separation between humans and electrical sources through barriers such as housings, insulation, or physical separation. It requires an IPXXD degree of protection for high-voltage (HV) components and an IPXXB degree of protection for access points, such as when cables are disassembled.

- Sneak Circuit Protection: This involves safeguarding against unexpected or unintended connections from HV live parts to exposed conductive parts. For example, Y-capacitors used for electromagnetic compatibility (EMC) protection can, if shorted, elevate the housing of a component to a dangerous HV level. Protection measures include ensuring very low impedance from conductive enclosures to the vehicle chassis and maintaining high impedance isolation from all HV buses to the vehicle chassis.

- Electrical/Electronic (E/E) Protection: In most production vehicles, E/E protection involves three key strategies: 1) discharging the HV bus, 2) monitoring the disconnection of HV cables and covers to HV components, and 3) monitoring the isolation resistance as required for sneak circuit protection. Design considerations for E/E protection include crash events, loss of 12V power, permanent magnet motors, and more. This layer is also where the automotive functional safety standard ISO 26262 is applied.

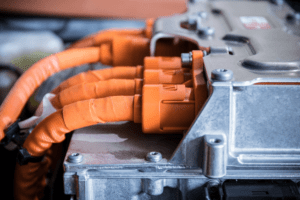

- Process Protection: This involves appropriate markings and labeling to ensure awareness of HV presence. This includes yellow triangles and orange insulation on HV cables as required by ECE R-100. Process protection also encompasses special instructions for production, maintenance, and first responders.

The safety of HV components and systems is ensured through these four layers of protection. We cover all these protection layers from a design perspective in our high voltage electrical safety training. More details on our training can be found here.